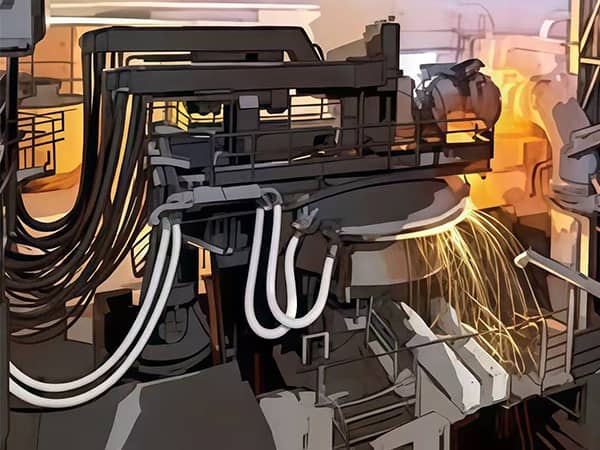

In the modern steelmaking industry, efficiency and safety are paramount. Whether it’s a converter, electric furnace(EAF), or other large-scale smelting equipment, their stable operation relies on a series of precise and reliable industrial hose systems. Among these, the electric furnace(EAF) cooling water rubber hose, as the “lifeline” ensuring the continuous operation of the equipment, plays an irreplaceable role in the extreme environment of high temperature and high pressure. Today, let’s explore the world of this seemingly ordinary yet crucial industrial component.

What is an Electric Furnace (EAF) Cooling Water Rubber Hose?

As the name suggests, an electric furnace(EAF) cooling water rubber hose is a flexible connecting hose used in the cooling system of an electric furnace(EAF). During the steelmaking process, the internal temperature of an electric furnace(EAF) is extremely high, reaching thousands of degrees Celsius. To prevent damage to the equipment due to high temperatures, a cooling water circulation system is necessary to continuously cool critical components such as the furnace body, electrodes, and furnace cover.

Unlike ordinary water hoses, electric furnace (EAF) cooling water rubber hoses need to possess excellent high-temperature resistance, high-pressure resistance, corrosion resistance, and fatigue resistance. It is typically installed around or inside the electric furnace(EAF), connecting fixed hoselines to moving equipment. It absorbs mechanical vibrations, compensates for installation errors, and can adapt to displacement changes within a certain range, ensuring a continuous and stable supply of cooling water.

Why are electric furnace(EAF) cooling water rubber hoses so important?

In steelmaking, a failure in the cooling system can lead to equipment overheating, furnace shutdown, or even safety accidents. High-quality electric furnace(EAF) cooling water rubber hoses can:

- Ensure continuous production: Resistant to high temperatures and pressures, avoiding unplanned production stoppages due to hoseline damage;

- Enhance safety: Explosion-proof and leak-proof design, protecting personnel and equipment;

- Reduce maintenance costs: Long lifespan and fatigue resistance, reducing replacement frequency and maintenance investment;

- Adapt to complex working conditions: High flexibility, easy to install in confined or dynamic environments.

As a professional manufacturer in the industrial rubber hose field, we are committed to providing high-performance, high-reliability hose solutions for industries such as steel, petrochemicals, and engineering. Whether it’s electric furnace(EAF) cooling water rubber hoses or key components such as steelmaking oxygen blowing hoses, we adhere to strict standards, advanced materials, and mature technology to safeguard our customers’ production safety and efficiency.

If you are looking for a reliable industrial rubber hose partner, please feel free to contact us. We will provide you with the most suitable products and services with a professional attitude, jointly contributing to the high-quality development of “Made in China”!

Click the website to learn more:www.unblockgroup.com

If you need any help in technical,please mail us (krystalqi@unblockgroup.com)